|

UMI-2000 Coal GAC 400 Activated Carbon

What are two types of Activated Carbon? Two types of Activated Carbon are Re-Agglomerated Coal based Activated Carbon manufactured

in the USA and Direct Activated "Crud" Carbon from Off-Shore (Asia). Re-Agglomerated Activated Carbon has up to 3 times the

Adsorptive Capacity of Direct Activated Carbon. Activated carbon treatment is the most studied treatment for PFAS removal.

Activated carbon is commonly used to adsorb natural organic compounds, taste and odor compounds, and synthetic organic chemicals

in drinking water treatment systems. Adsorption is both the physical and chemical process of accumulating a substance, such

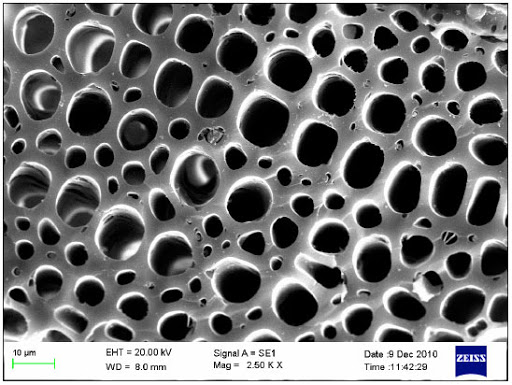

as PFAS, at the interface between liquid and solids phases. Activated carbon is an effective adsorbent because it is a highly

porous material and provides a large surface area to which contaminants may adsorb. Activated Carbon is made from organic

materials with high carbon contents such as bituminous coal, lignite coal, virgin coconut shells and is often used in granular

form called granular activated carbon (GAC). This highly porous carbonaceous material has been shown to effectively remove

PFAS and other organic contaminants from drinking water when it is used in a flow through filter mode after particulates have

already been removed. EPA researcher Thomas Speth says GAC can be 100 percent effective for a period of time, depending on

the type of carbon used, the depth of the bed of carbon, flow rate of the water, the specific PFAS needed to be removed, temperature,

and the degree and type of organic matter as well as other contaminants, or constituents, in the water. For example, GAC works

well on longer-chain PFAS compounds like PFOA and PFOS.

REMOVAL OF PFAS FROM GROUND AND SURFACE WATER with Granular Activated Carbon. Our top activated carbon made in the USA is

COAL GAC 400 RE-AGGLOMERATED GRANULAR ACTIVATED CARBON. DEMONSTRATES SUPERIOR ADSORPTION OF PFAS Compounds PFOA and PFOS from

water.

Benefits: Enables the removal of PFOA and PFOS from ground and surface water to non-detectable levels and well below the 70

PPT advisory level set by the EPA. Resists interference from Total Organic Carbon (TOC) for enhanced performance. Coal GAC

400 demonstrates much higher performance when compared to coconut-based GAC and direct activated coal based carbons commonly

referred to as "Crud Carbons". Coal GAC 400 lowers operating costs by enabling the treatment of more bed volumes of water

before change-out of spent Activated Carbon. PFOA (perfluorooctanoic acid) and PFOS (perfluoro-octane sulfonate), also known

as Poly- and perfluoroalkyl substances or PFAS, are man-made substances used in products such as non-stick cookware, waxy

food package coatings, water resistant clothing, stain resistant carpets and fabrics, and aqueous fire-fighting foams (AFFF).

Once in the environment, these chemicals are persistent, toxic, bio-accumulative, bio-transformative, and pose risks to human

health. In May 2016, the United States Environmental Protection Agency (EPA) established a human Health Advisory Limit (HAL)

of 70 ppt for the combined exposure concentration of PFOA and PFOS in drinking water.

When compared to direct activated "CocoCrud" coconut shell based carbons in surface and ground waters, actual third party

case studies and our tests found that Coal GAC 400 activated carbon demonstrated superior performance in the removal of PFAS

compounds. Unlike other types of granulated activated carbon (GAC), our Coal GAC 400 resisted interference from Total Organic

Carbon (TOC) that reduce the carbon adsorptive capacity for contaminants like PFOA and PFOS. In other studies involving groundwater

with low TOC, the performance of our activated carbon was also superior to other direct activated coal-based carbons and surpassed

direct activated coconut shell based carbon.

United Manufacturing International 2000 Re-Agglomerated Coal GAC 400 is a granular activated carbon for the removal of dissolved

organic compounds from water and wastewater as well as industrial and food processing streams. These contaminants include

taste and odor compounds, organic color, total organic carbon (TOC), industrial organic compounds such as TCE and PCE, and

PFAS. This Activated Carbon is made from select grades of bituminous coal through a process known as re-agglomeration to produce

a high activity, durable, granular product capable of withstanding the abrasion associated with repeated back-washing, hydraulic

transport, and reactivation for reuse. The raw coal is mined and subsequently manufactured into Granular Activated Carbon

in the United States to ensure the highest quality and consistency in the finished product. Activation is carefully controlled

to produce a significant volume of both low and high energy pores for effective adsorption of a broad range of high and low

molecular weight organic contaminants. Coal GAC 400 is formulated to comply with all the applicable provisions of the AWWA

Standard for Granular Activated Carbon (B604) and Food Chemicals Codex. This product may also be certified to the requirements

of NSF/ANSI 61 for use in municipal water treatment facilities.

Microscopic pore structure of coal based Activated Carbon.

Individual PFAS have different GAC loading capacities and corresponding breakthrough times (often defined as the number of

bed volumes treated prior to detection in the effluent) (Eschauzier et al. 2012). GAC removal capacity for PFOS is greater

than PFOA, but both can be effectively removed (McCleaf et al. 2017). In general, shorter chain PFAS ( e.g. PFBA perfluorobutanoate)

have lower GAC loading capacities and faster breakthrough times. However, influent concentrations for the shorter chain PFAS

are often an order of magnitude, or more, lower than the longer chain PFAS. For these types of applications where the influent

concentrations for the shorter chain PFAS are much lower and in the low ppt range, GAC can still be a cost-effective sorption

media option that meets applicable regulatory discharge criteria. Figure 12-1 provides an example of removal curves and breakthrough

information for a number of PFAS compounds. Note that all of the PFAS molecules with the exception of the short chain PFBA

are adsorbed and removed down to 70ppt MCL even after 100,000 BV

Specifications Coal GAC 400

Iodine Number 1000 mg/g

Moisture by Weight 2% (max)

Effective Size 0.55 - 0.75 mm

Uniformity Coefficient 1.9 (max)

Abrasion Number 75 (min)

Screen Size by Weight, US Sieve Series

On 12 mesh 5% (max)

Through 40 mesh 4% (max)

Typical Properties Coal GAC 400

Apparent Density 0.54 g/cc

Water Extractables <1%

Non-Wettable <1%

If you have detected PFCs in your water and require removal to below the MCL of 70 ppt, United Manufacturing International

can mobilize Activated Carbon Adsorbers and Coal GAC 400 Activated Carbon to your site. Typical removal efficiencies on our

Coal GAC 400 are down to ND. Send us your operating parameters, concentrations of PFCs, RFQ/RFB and we will provide our professional

proposal to compete for your business. The U.S. Environmental Protection Agency (EPA) on Wednesday released drinking water

health advisories for four per- and polyfluoroalkyl substances known as PFAS. Those included PFOA, PFOS, PFBS, and GenX.

The Upshot

The EPA 2022 interim health advisories for PFOA (0.004 ppt) and PFOS (0.020 ppt) are orders of magnitude lower than the

2016 health advisories or any state-level enforceable drinking water standards. The new PFOA and PFOS interim health advisories

come in advance of the EPA highly anticipated proposed Maximum Contaminant Level Goals to support the Safe Drinking Water

Act National Primary Drinking Water Regulations for PFOA and PFOS. Those goals will be published later this year. The severely

reduced health advisories beg the question: Can laboratories detect PFOA at 0.004 ppt or PFOS at 0.02 ppt?

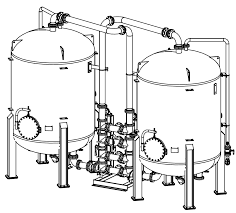

Activated Carbon Adsorber Contactors

Back to Home Page

|