|

Both Quality AND Quantity are our Trade Mark in Activated Carbon and Adsorbers, Ion Exchange Resins and all the support services

from design set, Sizing, CAD drawings, use-rate estimates, costing and quoting, delivery, installation and start up of your

Adsorption Filtration System with Coal GAC 400 Activated Carbon.

UMI-2000 know activated carbon! We know how to control the activation process to produce an Activated Carbon best suited to

your application. For maximum removal capacity of your target contaminants critical procedures during the manufacture of our

GAC are carefully designed to produce a final product of high hardness, low ash, exact particle size and low fines content

- all with superior volume activity, well developed pore structure and exceptional adsorptive capacity. Our "triple-check"

QC system assures the specifications of your activated carbon. Additional procedures we perform regularly on our premium

grades of activated carbon are 1. Proper selection of base raw material. 2. Crushing/Pulverizing and Re-Agglomeration (NOTE:

Direct activated Carbon has only 1/3 the adsorptive capacity of Coal GAC 400 Re-Agglomerated Activated Carbon which is mined

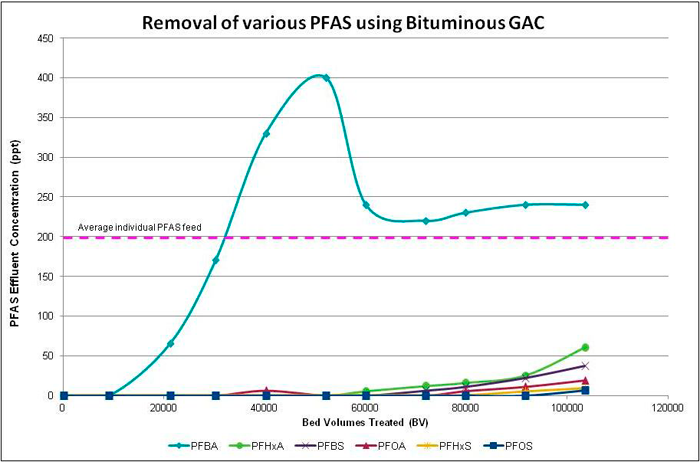

and manufactured in the USA - Off-shore activated carbons display premature breakthrough in our column tests). Three carbon

change-outs are required with direct activated - carbon when compared to only one change-out over the same time period with

the Coal GAC 400 re-agglomerated 12x40 mesh high activity Granular Activated Carbon. So the direct activated carbon causes

an increase of 2 extra change-outs for a total of 3 change-outs. With Coal GAC 400 only one change-out would be required over

the same time period. Do the math - the $cost savings with Coal GAC 400 re-agglomerated GAC are staggering! (We proved it

with RSSCT Tests) Our GAC works faster and lasts longer than direct activated carbon. If you read any list of non-acceptable

carbon types for most USA Water Treatment Plants they will NOT accept 1. crushed pellets 2. direct activated 3. lignite 4.

sub-bituminous coal 5. Anthracite 6. Coconut shell based Activated Carbon etc. Further screening, de-dusting and acid washing

are performed on our carbon to reduce ash and fines content of our activated carbon.

UMI-2000 premium Activated Carbons are shipped in heavy duty re-useable packaging including double woven double stitched

UV and tear resistant 1000 or 1100 lb super sacks with down-spout on the bottom for a clean flow of carbon into your vessel

by gravity feed. 200 lbs fiber drum with locking lid or 50-55 lb PP woven bags - shrink-wrapped and palletized - shipped

from nationwide warehouses for prompt delivery. Adsorption systems are designed using advanced computerized isotherm programs.

We can accurately predict contaminant loading and premature break through empirical data tested in our laboratory with RSSCT

(Rapid Small Scale Column Test - pictured above) or we can calculate a good estimate to get basic sizing of the vessels from

advanced Activated Carbon Isotherm computer programs. Send your operational parameters, flow-rate, contaminants (adsorbates)

and concentrations, source of the water to be treated and location, Temperature, water analytical, target contaminants to

be removed, MCLs etc. and let us design, size, build, deliver, install, start-up and service a full scale Activated Carbon

Adsorption Filtration System for you!

UMI-2000 is as USA Supplier of Activated Carbon and Adsorption Filter Vessels.

United Manufacturing International 2000 Activated Carbon Adsorption Filter Vessels, Charcoal Scrubbers, Contactors, Columns,

Canisters, Barrels, Cylinders, Drums, Towers & Tanks, Sorption Units & Systems to remove synthetic organic chemicals

(SOC), Volatile Organic Compounds (VOC), the Forever Chemicals, CEC Contaminants of Emerging Concern, PFAS, PCB, BTEX, DDT

from drinking water with AquaCarb® enhanced coconut shell Granular Activated Carbon-or-COAL GAC 400 Re-Agglomerated Activated

Carbon.

E-mail your RFQ to:

zardoz823@gmail.com

CALL NOW!: 530-349-1122

Page-Up

|

|